Facade Panels

Façade panels are used in all buildings due to their wide range of surface designs and finishes. BIM is our primary construction approach, which offer moisture protection and closure during the construction process. It is appropriate for densely populated metropolitan

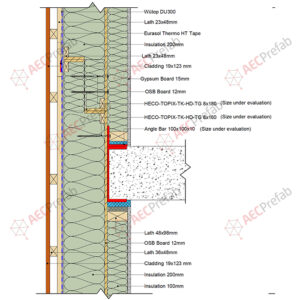

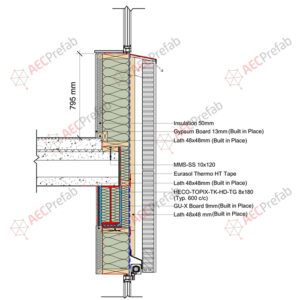

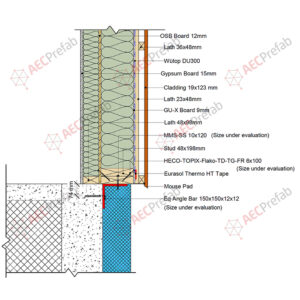

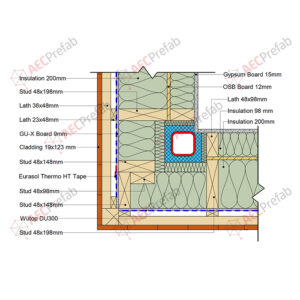

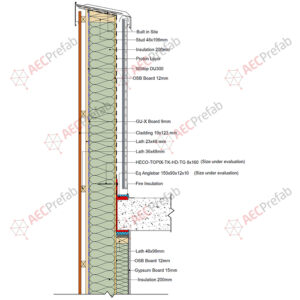

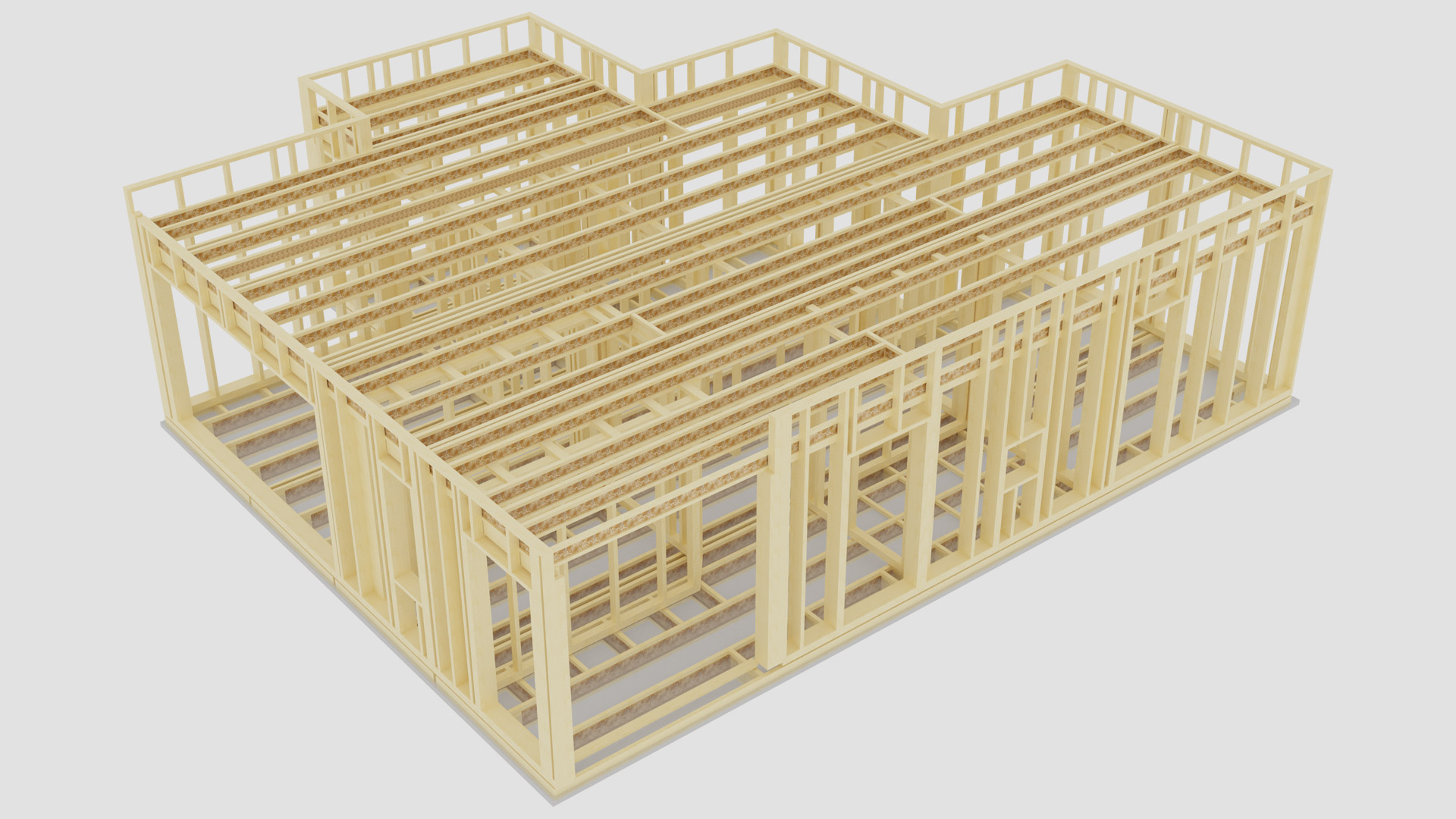

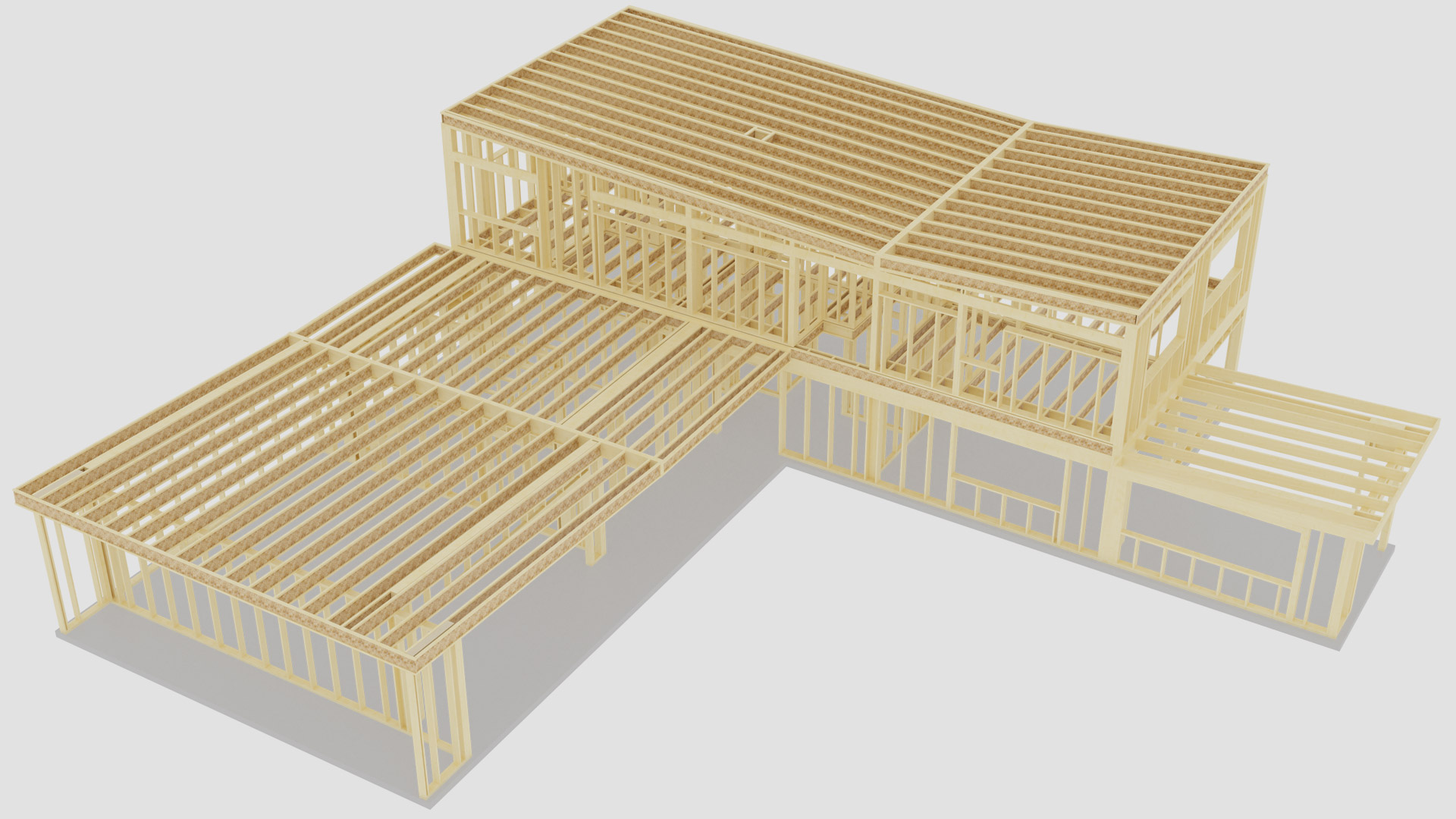

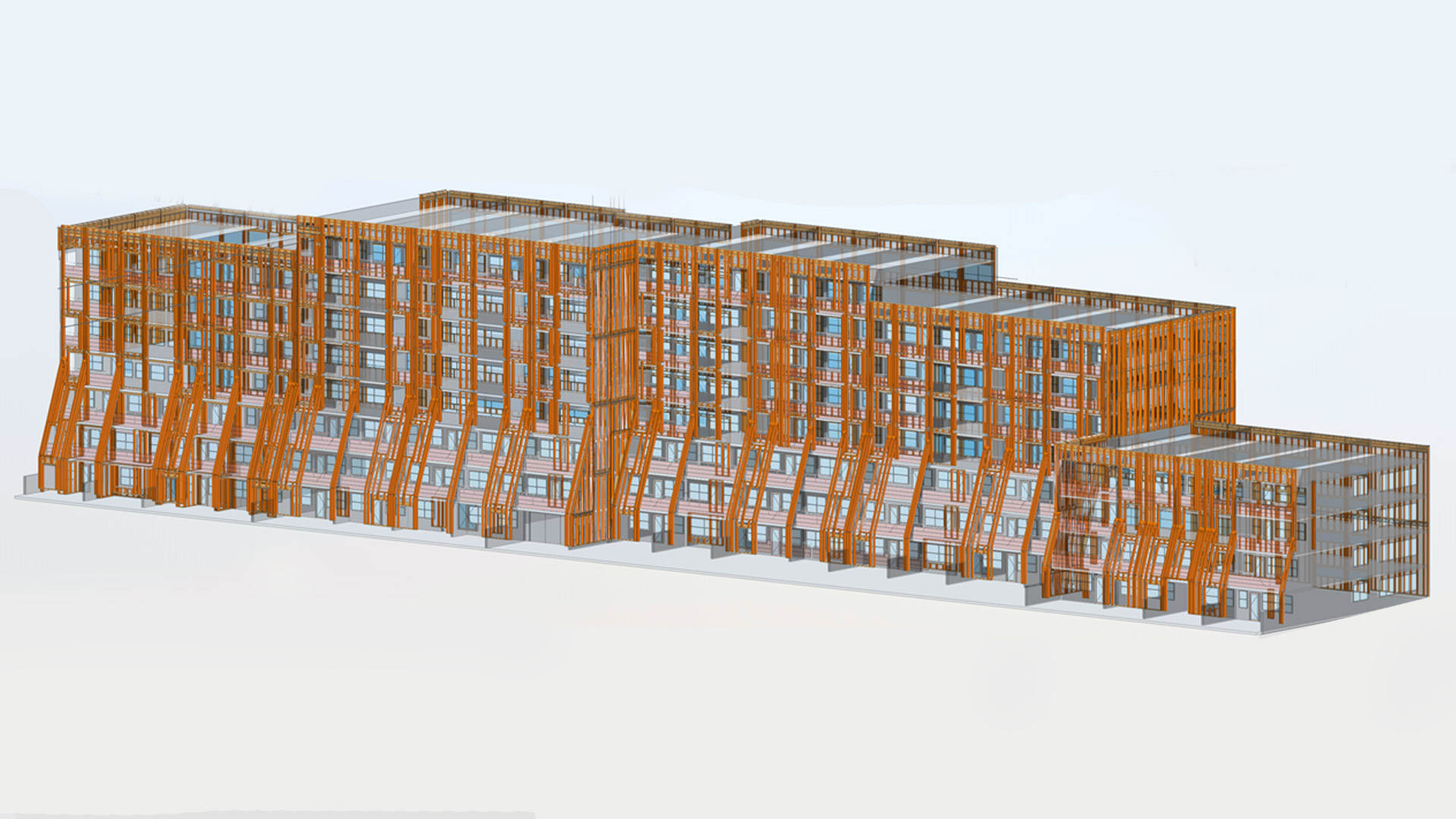

regions with restricted space needs. Façade panels are framework panels that serve as a foundation or fill-in panels on each floor, supported by a slab. AEC Prefab always prefers these external prefers these external wall panels as the foundation to achieve a simple connection for static performance, having high energy efficiency, less installation time, and more economical. The 200-300mm stud-height façade wall panels have a solid insulating layer external to the concrete slab. Doors, windows, sunshade, and vertical water pipes are customizable to client requirement and fixed to these panels. The framework has an OSB barrier to maintain the moisture barrier, solidity, and rigidity of the panels during transportation and installation. When the outer wall and the products such as electrical sockets, junction boxes, or any ventilation facilities seal in the building site, the inner walls of the façade panel with the size of 50-100mm are installed. External finishing is based on personal desire. AECP always prefers horizontal and vertical claddings for factory installation. However, only a few sections will be left for the construction company to connect and seal on-site.

Façade Panels for Renovation Projects

Façade panels influence the energy performance, lifecycle cost, building performance, physical behaviour, durability, and aesthetics of external walls in renovation and new-build construction projects. AEC Prefab addresses the problems due to airtightness or face-lift with different solutions for renovation due to the deterioration and carbonation of a concrete façade. AEC Prefab creates precise drawings for the connection and documents static performance in collaboration with the architect. AEC Prefab works with point clouds, drone data, and photogrammetry to generate geometrical data and surface topography. AEC Prefab collaborates with several manufacturing companies to assemble and produce the prefabricated wall and façade panels. AEC Prefab requires the highly automated CNC-based manufacturing approach to manufacture prefabricated wood panels, which are made based on the assembly line method. Customized wood panels with complete insulation, side sheathing, and finished façade reduce the assembly time, moisture and other weather challenges during the construction and future problems.

Connection Details of Facade Panels

Some of Our Projects

Build Your Own Designs

Register and get the visual experience